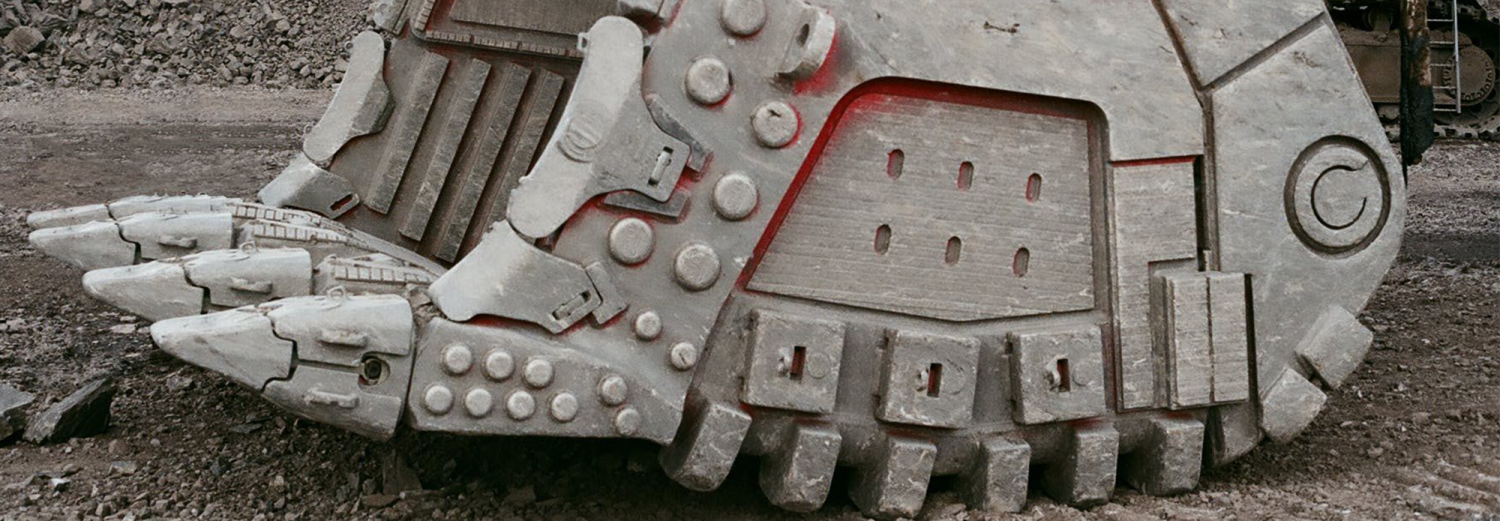

The primary reason of using a hardfacing alloy is to increase the life of parts while RhinoWear Alloy consumable range also adds the extra Rhino punch. So if you are using a RhinoWear alloy for abrasive wear resistance, you can rest assured our handpicked carbides in those alloys will provide longer life to your equipment and machinery parts.

Our range includes RhinoWear wearfacing CrC electrodes, extreme resistance tungsten carbide tubular electrodes and high productivity RhinoWear flux packed wires.

WELDTRODE m09

Flux cored wire having complex carbides in a tough matrix, especially used for maximum abrasion resistance at higher temperatures.

Optimal usage: Sieves in steel plant, cement kilns, etc. where abrasion at high temperatures in excess of 600° C is encountered.

Metal Chemistry: C = 4.10% Mn = 1.3% Mo = 5.0% Cr = 21.0% Nb = 6.0% Si = 1.0% V = 0.8% W = 2.0%

Hardness 3 Layers: 60 – 62 HRc

Polarity: DC wire positive

Size: 2.40mm and 2.80mm

Packing: 15kg spools sealed in polythene bag and shrink wrapped in a corrugated box. 2.4 and 2.8mm wires available in 250kg fiber drums for automatic welding.

Weldtrode m06

A self-shielded high carbon high chromium flux cored wire designed especially for extreme wear & abrasion conditions. The weld deposit is primarily used for hard facing components subjected to extreme abrasion/erosion under moderate/ heavy impact loads. The weld deposit contains a high proportion of hard primary chromium carbides in a tough martensitic- secondary carbide eutectic matrix. The weld deposit is nonmachinable.

Optimal usage: Worn out Ni-Hard and high chrome crusher rolls, table liners, tires etc. for the coal mills in thermal power stations and crushing mills in cement plants. Gyratory crusher cones and mantles, catalyst pipes and bends, slurry pipes and value bodies, dredge pump bodies, extruder screws, mining and earthmoving equipment, blast furnace bells, coal pulverize rolls, crusher hammers, shovel edges wear plates, etc.

Metal chemistry :C= 5.00% Si= 1.00% Mn=1.1% Cr=25.0-28.0%

Hardness 3 Layers: 55-58 HRC

Polarity: DC wire positive

Size: 1.60mm, 2.00mm, 2.40mm, 2.80mm

Packing: 15.00 kgs spool sealed in polythene bag and shrink wrapped in a corrugated box. 2.4 and 2.8mm wires are available in 250kgs fiber drum for automatic welding

Wire extension (stickout): 35-40mm

WELDTRODE M74

A self-shielded high carbon high chromium flux cored wire designed especially for extreme wear & abrasion conditions. The weld deposit is primarily used for hard facing components subjected to extreme abrasion/erosion under moderate/ heavy impact loads. The weld deposit contains a high proportion of hard primary chromium carbides in a tough martensitic- secondary carbide eutectic matrix. The weld deposit is non-machinable.

Optimal usage: Worn out Ni-Hard and high chrome crusher rolls, table liners, tires, etc. for the coal mill in thermal power stations and crushing mills in cement plants. Gyratory crusher cones and mantles, catalyst pipes and bends, slurry pipes and value bodies, dredge pump bodies, extruder screws, mining and earthmoving equipment, blast furnace bells, coal pulverize rolls, crusher hammers, shovel edges wear plates, etc.

Metal chemistry: C= 4.5% Si= 1.00% Mn=1.00% Cr=16.0-20.0%

Hardness 3 Layers: 53-56 HRC

Polarity: DC wire positive

Size: 1.60mm,2.00mm,2.40mm, 2.80mm

Packing: 15.00 kgs spool sealed in polythene bag and shrink wrapped in a corrugated box. 2.4 and 2.8mm wires are available in 250kgs fiber drum for automatic welding

WELDTRODE S06

A self-shielded high carbon high chromium flux cored wire designed especially for extreme wear & abrasion conditions. The weld deposit is primarily used for hard facing components subjected to extreme abrasion/erosion under moderate/ heavy impact loads. The weld deposit contains a high proportion of hard primary chromium carbides in a tough martensitic- secondary carbide eutectic matrix. The weld deposit is non machinable.

Optimal usage: Worn out Ni-Hard and high chrome crusher rolls, table liners, tiress etc. for the coal mills in thermal power stations and crushing mills in cement plants. Gyratory crusher cones and mantles, catalyst pipes and bends, slurry pipes and value bodies, dredge pump bodies, extruder screws, mining and earthmoving equipment, blast furnace bells, coal pulverize rolls, crusher hammers, shovel edges wear platess etc.

Metal chemistry: C= 5.00% Si= 1.00% Mn=1.00% Cr=30.0-34.0%

Hardness 3 Layers: 57-60 HRC

Polarity: DC wire positive

Size: 1.60mm,2.00mm,2.40mm, 2.80mm

Packing: 15.00 kgs spool sealed in polythene bag and shrink wrapped in a corrugated box. 2.4 and 2.8mm wires are available in 250kgs fiber drum for automatic welding.

WELDTRODE ME71 T1 (Mild Steel)

For welding of mild steel & carbon steel for machinery fabrication, ships, bridges, structures, steel frames etc.

Weld metal chemistry (with CO2 shield): C= 0.10% Max, S=0.025% Max, Mn=1.00 to 1.60%, P=0.025% Max, Si=0.55%

Shielding Gas: CO2 or Argon +20% CO2 gas with flow rate of 15- 20 litres/minute.

Characteristics: Rutile based flux cored wire suitable for all position welding with DC electrode positive. The wire produces a full slag coverage and excellent slag detachability. The welding arc is smooth and stable with low spatter and good bead appearance.

Polarity: DC wire positive

Size: 1.60mm

Welding position: All

Packing: 15.00 kgs spool sealed in polythene bag and shrink wrapped in a corrugated box