Chromium carbide wear plates have been around for more than 75 years. Pioneers in this field have used various bulk welding processes to produce plates with the best properties. Each of those processes came with their own strengths. Rhino Wear Products took the best out of each and the result is our proprietary RhinoWear plates.

RhinoWear plates use our own developed “Xtra High Deposit” process whereby we can add more alloy elements per square meter to the plate when compared to other processes. This gives our RhinoPlate® extreme strength in combating wear.

RhinoPlate® is unique because the overlay is applied in a chevron pattern. This allows the plate to be cut and formed using the plate the most effective way and minimizes waste. Typical chromium carbide wear plate runs the overlay in one direction which limits which way the plate can be formed and/or cut. RhinoPlate’s chevron pattern allows even wear and prevents washing between the weld seams.

To learn more about our plates please contact a Rhino Wear Expert.

Rhinoplate® AWP99

Our standard plate; it’s a rich carbide wear plate with a balance of C-Cr-Si to ensure good abrasion wear resistance and moderate impact. The typical hardness in AWP99 is 54-58 HRc. This plate is widely accepted as a standard in several wear part applications across the globe.

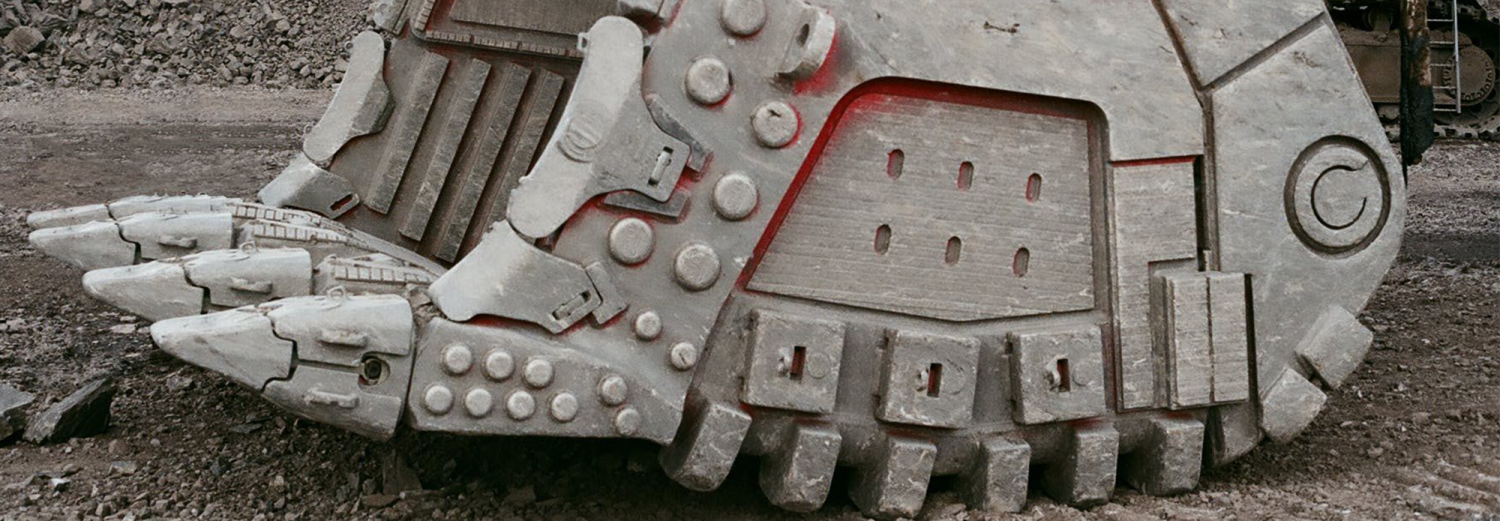

Typical applications: Covers all major abrasive wear needs of cement, mining, steel and other high wear industries; Buckets, Louvers, Mill Liners, Dozer Blades and Nozzle Covers to name a few.

Rhinoplate® AWP99Xtra

A high percentage carbide C-Cr-Si-Mn plate which is excellent against extreme abrasion and erosion wear resistance. The chromium percentage for AWP99Xtra reaches up to 32% making it ideally suitable for high wear application. The typical hardness is 58–62 HRc.

Typical Applications: Used in cases of extreme abrasive and erosive wear needs of cement, mining, steel and other high wear industries; Separators, Roller Guards, Batch Mixing Spares and many more.

Rhinoplate® SlimHard

A rich complex of carbide alloys including Tungsten and Niobium on a thin base metal; why use a thicker plate when a thin plate has a higher wear resistance?

A high percentage of C, Cr, Nb, W, B, Mn, Si and balance Fe; Slimhard plate offers extreme abrasion resistance with high amount of phases retaining hardness under high temperatures. The typical hardness is 62–65 HRc.

Microstructure: Hyper-Eutectic with M7C3 primary carbides in an austenitic eutectic matrix.

Typical service temperature: 800° C

Carbide share (%): Greater than 45% primary carbides.